|

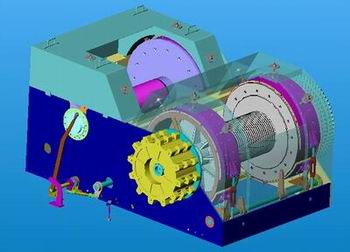

1.Drawworks of workover rig

The Drawworks

is one of the core components of workover rig have two structures: single &

double drum, includes main (sand) drum assembly, main (sand) drum brake system,

Drawworks frame, cooling system, lubrication system, auxiliary brake, crown

block anti-collision device etc. mainly used for rising & lowing drilling

tool and lowing casing, controlling bit weight in process of drilling well,

sand drum is used for extracting core barrel, testing oil etc working.

|

Item

|

technical parameter

|

|

JC08

|

JC12

|

JC18/11

|

JC21/11-C

|

JC28/11

|

|

kW

Input power

|

150

|

180

|

400

|

450

|

600

|

|

Main drum

|

kN

Max. fast pull (the second layer )

|

80

|

120

|

180

|

210

|

280

|

|

mm

Drum dia. x length

|

Φ345×590

|

Φ356×912

|

Φ450×912

|

Φ450×912

|

Φ580×1012

|

|

mm

Brake drums (disc) dia. x length (thichness)

|

Φ810×210

|

Φ970×260

|

Φ1070×310

|

Φ1070×310

|

Φ1168×267

|

|

mm

Applicable line dia.

|

22

|

22

|

29

|

29

|

32

|

|

rpm

Max. rotary speed

|

450

|

450

|

450

|

450

|

450

|

|

Cooling type of brake drum

|

Air cooling

|

Air cooling

|

Forced circulation water cooling

|

Forced circulation water cooling

|

Forced circulation water cooliong

|

|

Sand drum

|

m

Rope capacity

|

|

|

2500m (9/16in)

|

2500m (9/16in)

|

2000m(φ16mm)

|

|

mm

Drum dia. x length

|

|

|

Φ345×912

|

Φ345×912

|

Φ360×960

|

|

mm

Brake drum dia. x length

|

|

|

Φ970×210

|

Φ970×210

|

Φ970×210

|

|

kN

Max. pulling force(the second layer)

|

|

|

110kN

|

110kN

|

110kN

|

|

rpm

Max. rotary speed

|

|

|

450

|

450

|

450

|

2.winch for swabbing unit

The winch of swabbing unit is the one of core

components of swabbing truck, according to drum rope capacity, the winch is

divided into four specification: 2000m, 2500m, 2700m and 3000m. Material of

drum body and guard plate are both made of welded low-alloy structural steel,

mainly include main drum assembly, drum brake system, winch frame etc, mainly

used for lifting & lowing swab and fishing tool when oil recovery and

fishing operations.

|

model

parameter

|

YJC03

|

YJC08

|

YJC08A

|

YJC08B

|

YJC12

|

YJC12A

|

YJC12B

|

YJC12C

|

|

m

Rope capacity

|

1200

|

2000

|

2500

|

2000

|

2500

|

2700

|

2500

|

3000

|

|

kN

Max. lifting force at min.

diameter

|

30

|

60

|

80

|

80

|

120

|

120

|

120

|

120

|

|

mm

Wireline dia.

|

13

|

16

|

16

|

16

|

16

|

16

|

16

|

16

|

|

mm

Drum dia. x length

|

Φ324×590

|

Φ345×910

|

Φ360×561

|

Φ360×527

|

Φ380×966

|

Φ380×966

|

Φ380×966

|

Φ410×966

|

3.winch of wireline unit

The winch

is core components of wireline unit, Users can replace the arrangement wire

hanging pulley according to wire specifications to meet different operational

requirements. It can be divided into steel drum winch, double drum winch, mobile

drum winch, mainly consists of the winch frame, drum body , brake device ,

arrangement wire mechanism, deep and weight indicating device and hand

mechanism and other components . Winch adopts variable speed, which is not

necessary to passing transmission box to change winch speed, with simple

operation and saving effort, low noise, smooth and reliable; brake adopts no

dead-end outsourcing dual brake belt brake mechanism, hand brake devices, hand

mechanism are installed in operation compartment, with flexible operation, safe

and reliable; Equipped with automatic arrangement wire device, which reduces

labor intensity.

|

model

parameter

|

SJC40

|

SJC60

|

SJC75

|

double drum

|

|

Wire drum

|

Cable drum

|

|

(mm)

Drum dia.

|

f200

|

f150 mm

|

f210

|

≥f200

|

≥f300

|

|

(mm)

Drum body length

|

396

|

396

|

504

|

144

|

252

|

|

(mm)

Dia. of brake rim

|

f390

|

f390

|

f390

|

f505

|

f505

|

|

Drum

capacity (wireline dia.)

|

≥4500 m(f2.8mm)

|

≥6500 m(f2.4mm)

|

≥7500 m(f3.2mm)

|

≥6000m(f2.4mm)

|

≥6000m(f2.4mm)

|

|